Hey there, shoe enthusiasts! We all love a good pair of kicks, right? But have you ever thought about the impact that our beloved footwear has on the environment? Well, buckle up, because today we’re diving into the fascinating world of water-saving footwear production methods. It’s all about making those comfy sneakers in a way that’s kind to our planet. Let’s get into it!

Read Now : Trendy Ergonomic Footwear For Professionals

The Essence of Water-Saving Footwear Production

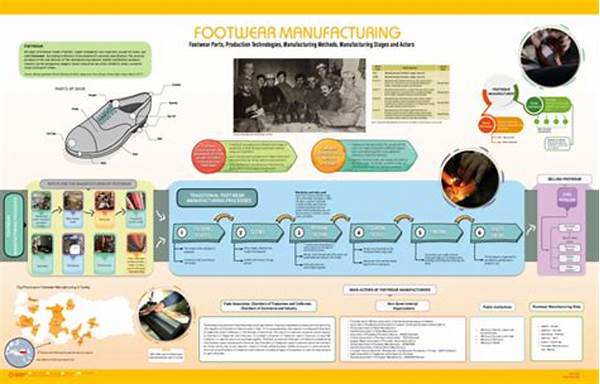

Imagine a world where making shoes doesn’t guzzle gallons of water. That’s the goal of water-saving footwear production methods, and it’s not just a dream anymore. Many footwear brands are innovating ways to reduce water usage in their production processes. Not only does this help save our precious H2O, but it also shrinks the carbon footprint of making shoes. Picture this: traditional tanning and dyeing processes require heaps of water, but with new eco-friendly technologies, companies are cutting down water use by up to 50%! Isn’t that awesome?

What’s more, these methods often use recycled materials, adding another layer of sustainability. From using water-based adhesives to implementing closed-loop systems, the industry is embracing change. Water-saving footwear production methods aren’t just a trend; they’re a necessary shift for a sustainable future. So next time you slip on a pair of eco-conscious sneakers, remember the journey they went on to be gentle on our planet.

Innovative Techniques in Water-Saving

1. Dyeing Innovations: Brands are switching to waterless dyeing processes, drastically cutting down water usage.

2. Recycled Materials: Utilizing materials like recycled rubber and polyester reduces the demand for water-intensive new resources.

3. Adhesive Alternatives: Water-based adhesives replace traditional ones, which are often chemical-heavy and water-intensive.

4. Closed-Loop Systems: Companies are adopting systems where water is reused rather than expelled, saving substantial amounts of water.

5. Digital Printing: Instead of traditional printing, digital methods require far less water during pattern creation.

The Future of Footwear Production

As we march forward, the future of shoes looks greener and cleaner, thanks to water-saving footwear production methods. These methods aren’t just about reducing water use; they’re about reshaping the entire manufacturing process. From sourcing materials to delivery, every step is being reimagined. Brands are setting ambitious targets, aiming for zero water waste in their processes. Imagine every brand committing to such initiatives—our planet could see a notable positive shift.

Moreover, these techniques encourage innovation and creativity. Companies are now exploring materials we wouldn’t have thought possible in footwear, like algae and pineapple leather. Such advancements wouldn’t have been conceivable without the urgency brought on by climate change and resource scarcity. The drive for water-saving footwear production methods has also fostered a mindset of accountability within the industry. No longer is sustainability a side note; it’s becoming central to business models.

Challenges and Opportunities

Of course, embracing water-saving footwear production methods isn’t without its challenges. For instance, the initial costs of adopting new technologies can be steep. However, in the long run, these costs balance out as companies save on raw materials and water. Moreover, consumer demand for sustainable products is at an all-time high, creating market opportunities for companies willing to adapt.

Read Now : Quality Running Shoes At Low Prices

Another challenge is educating consumers about the importance of these methods. While eco-conscious customers are on the rise, not everyone is aware of the behind-the-scenes efforts companies are making. It’s crucial for brands to not only adopt these methods but also shout it from the rooftops (figuratively speaking, of course). As awareness grows, so too will the desire for water-saving footwear, encouraging more brands to take the plunge into sustainable practices.

Examining the Impact

The shift towards water-saving footwear production methods is already having a tangible impact on our planet. Companies dedicated to this cause are reporting significant reductions in water consumption. Not only does this aid in conserving global water supplies, but it also sets a precedent for other industries to follow suit. As more brands adopt these methods, a ripple effect occurs, influencing beyond footwear. Could water-saving production become a norm across all industries? It’s a hopeful thought.

We’ve also seen a boost in consumer trust and brand loyalty. Shoppers are more inclined to buy from companies that demonstrate genuine environmental commitment. In turn, this fosters a community of advocates who support and promote these brands. Water-saving footwear production is only the beginning, but it’s a foundational step towards comprehensive environmental responsibility.

A Brighter Path Forward

The journey towards widespread adoption of water-saving footwear production methods is just getting started. As new technologies emerge, these methods will only improve. It’s an exciting time to be a part of both the fashion and sustainability sectors. There’s a shared understanding that future generations depend on the actions we take today. By choosing water-saving methods, the footwear industry is leading by example in corporate responsibility.

In conclusion, next time you’re shopping for shoes, why not consider a pair made using water-saving footwear production methods? Not only are you making a stylish choice, but you’re also supporting sustainability. Let’s encourage these indelible practices, champion environmental stewardship, and take steps—literally and figuratively—toward a planet-friendly future.

Summarizing the Shift

In summary, the movement towards water-saving footwear production methods is reshaping the shoe industry one step at a time. Traditional processes are being replaced by innovative, sustainable alternatives that drastically reduce water usage. This shift not only conserves essential resources but also sets a benchmark for eco-friendly production across industries. The commitment to reduce water consumption aligns with a broader goal of decreasing the environmental footprint of manufacturing as a whole.

By reassessing every aspect of production, from material sourcing to adhesives used, the shift is comprehensive. And while challenges such as cost and consumer education remain, the benefits outweigh the hurdles. We’re now in an era where customers are valuing more than just style; they care about sustainability too, and brands are listening. The continued push for water-saving methods signifies a promising and necessary path forward for a sustainable fashion industry.