Hey there! Ever wondered about the life cycle of that package you just threw out? Don’t worry; you’re not alone. You’re about to dive into the world of life cycle assessment (LCA) in packaging. It’s a fascinating journey that takes you through the cradle-to-grave journey of packaging materials. So, buckle up as we unravel why understanding the environmental footprint of packaging is more crucial than ever.

Read Now : Walking Shoes For Flat-footed People

What is Life Cycle Assessment in Packaging?

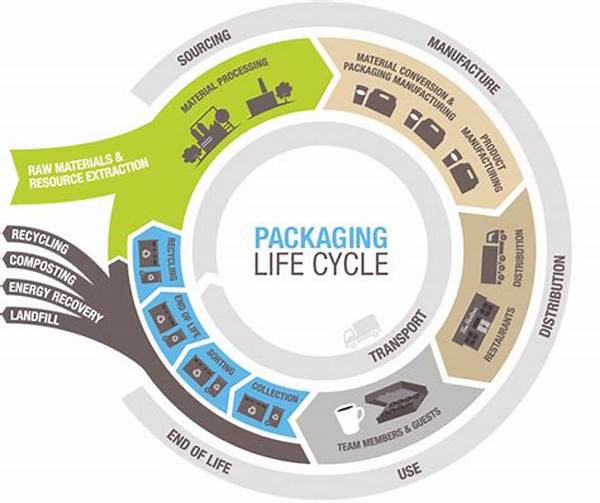

So, you’re probably thinking, what exactly is life cycle assessment in packaging? Great question! In simple terms, it’s a method that evaluates the environmental impacts of a packaging product throughout its entire life—from raw material extraction to disposal. Imagine tracking a milk carton from the tree that grew the pulp to the recycling plant where it ends up. LCAs help companies and consumers alike understand the total environmental cost of packaging. It’s like having a full report card on how packaging contributes to pollution, energy use, and carbon footprint. For companies, this assessment can be a game-changer, guiding sustainable choices and responsible production. It’s an eye-opener, making everyone more aware of the hidden impacts of everyday items.

Benefits of Life Cycle Assessment in Packaging

1. Eco-Friendly Decisions: Companies can make more sustainable packaging choices by using life cycle assessment in packaging, smartly designing products that leave a lighter ecological footprint.

2. Material Selection: LCA guides in choosing materials that are less harmful to the environment, promoting recycling, and waste reduction.

3. Cost Efficiency: By identifying environmental inefficiencies, life cycle assessment in packaging can lead to cost reductions in material, energy consumption, and waste management.

4. Regulatory Compliance: It ensures that packaging designs meet environmental regulations, mitigating the risk of legal issues and penalties.

5. Consumer Trust: Brands that adopt life cycle assessment in packaging demonstrate transparency and commitment to sustainability, winning consumer trust and loyalty.

Read Now : Advanced Techniques In Shoe Manufacturing

Life Cycle Assessment in Packaging: Challenges & Opportunities

Life cycle assessment in packaging comes with its set of challenges and opportunities. On the downside, obtaining accurate data across every stage of a product’s life can be daunting. Imagine tracking every bit of energy or emissions from every step in the production process! However, this challenge presents opportunities for innovation. Companies are encouraged to create new methodologies or technologies for better data gathering and analysis. Furthermore, there’s a growing opportunity in transparent communication. Brands can share findings from their LCAs to inform and educate consumers. More educated consumers can make better choices about the packaging they purchase, influencing market dynamics toward more sustainable options.

Implementing Life Cycle Assessment in Packaging

When diving into life cycle assessment in packaging, brands must start with a thorough understanding of their product life cycle. Generally, this involves mapping out all stages: material extraction, manufacturing, distribution, usage, and end-of-life. Each stage should be analyzed for environmental impact, like carbon emissions, water usage, or waste generation. Once the LCA is complete, the analysis can guide companies in making effective changes, whether by altering materials or optimizing processes. The success of an LCA lies in its implementation—by taking findings and turning them into actionable strategies, companies can markedly reduce their environmental footprint and improve sustainability efforts.

The Future of Life Cycle Assessment in Packaging

Looking ahead, the future of life cycle assessment in packaging is quite promising. As technology advances, the accuracy and ease of conducting LCAs will improve, potentially making them an indispensable tool for all packaging companies. Machine learning and AI could streamline data collection and prediction models, offering faster and more detailed assessments. Moreover, as consumer consciousness about environmental issues grows, the demand for transparency will likely drive more brands to adopt LCAs. Ultimately, integrating LCAs could become a standard in industry practices, leading to a more sustainable packaging future for the planet—and that’s a win-win for us all.

Conclusion

To wrap it up, life cycle assessment in packaging is not just a buzzword or trend—it’s a vital practice for achieving environmental sustainability in the packaging industry. It offers insights that can drive innovation and efficiencies while contributing to eco-friendly practices. Through continuous improvements and innovations in LCAs, both companies and consumers can play a part in reducing the overall negative environmental impact. By understanding the full journey and impact of packaging, we can make conscious choices that align with a sustainable future, ensuring that packaging serves its purpose with the least ecological damage possible. So, next time you toss a package, remember the journey it underwent and how our choices can shape a greener world.