So, you’re into shoes, right? Whether you’re strolling down the street or running a marathon, footwear is essential. But have you ever thought about what happens to your kicks after they’re worn out? Enter the world of closed-loop footwear production systems—an innovative approach that’s changing the game in sustainable fashion. Imagine a world where your worn-out sneakers don’t add to the landfill but instead become part of a new pair. Intrigued? Let’s dive in.

Read Now : Cushioned Shoes For Food Service Workers

Why Closed-Loop Footwear Production Systems Matter

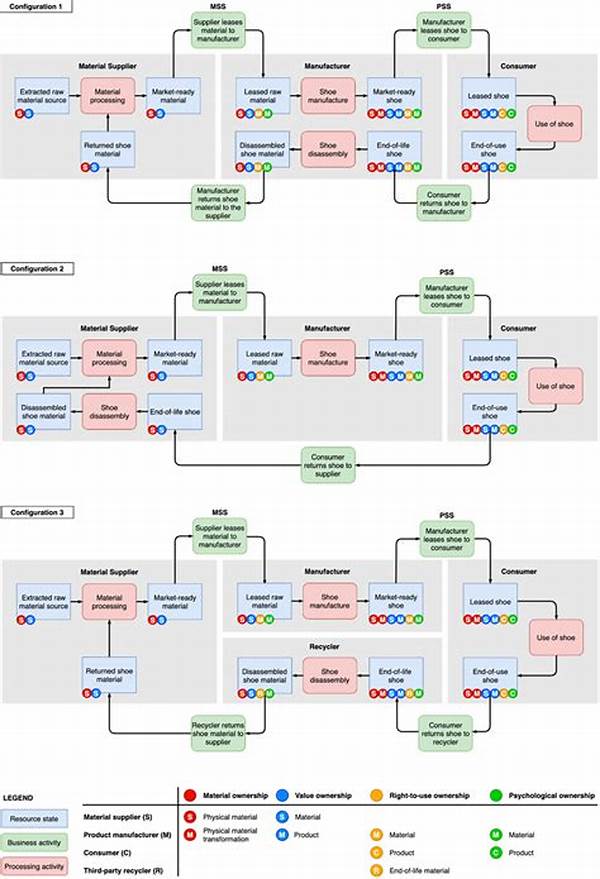

In a world that’s slowly but surely waking up to environmental issues, closed-loop footwear production systems are more crucial than ever. Why, you ask? Well, these systems are all about reducing waste and reusing materials, creating a sustainable environment. Simply put, the concept involves designing shoes that can be easily recycled or decomposed. The materials from old footwear are extracted and repurposed, going back into the production cycle for new shoes. This not only reduces the waste going to landfills but also cuts down on the need for raw materials like rubber and leather. Plus, with consumer awareness at an all-time high, brands that adopt these methods are gaining a competitive edge. It’s all about the triple win—great for you, awesome for the planet, and beneficial for the brands.

The Basic Elements of Closed-Loop Footwear Production Systems

1. Design for Deconstruction: One of the key aspects of closed-loop footwear production systems is creating shoes that can be easily taken apart. This makes recycling the materials a whole lot easier.

2. Material Recovery: Old shoes are scanned for reusable parts. Rubber soles, for example, can be ground down and used in new soles. It’s all about maximizing the lifespan of each component.

3. Energy Efficiency: Closed-loop footwear production systems focus on using less energy than traditional methods. By constantly repurposing materials, energy consumption goes down.

4. Consumer Engagement: Some brands even offer incentives for bringing old shoes back, letting customers feel part of the solution.

5. Transparency and Traceability: Ever wanted to know where your shoes were really made? These systems often incorporate full traceability, so you can cherish each step of your shoes’ lifecycle.

Read Now : Flat Foot Runners Shoe Guide

How Brands are Adopting Closed-Loop Footwear Production Systems

The shift towards closed-loop footwear production systems isn’t just happening overnight. Brands are investing serious time and money to ensure they’re part of this eco-friendly wave. Some companies are opting for biodegradable materials, while others are perfecting the art of recycling. Imagine returning your sneakers in exchange for a discount on your next pair; customers are loving it. And let’s face it: who doesn’t like a discount? Brands are also creating partnerships with recycling facilities to make the process seamless. The goal is to make closed-loop systems mainstream, moving past a trend and becoming the new norm for tomorrow’s footwear. It’s an exciting time to be a shoe lover, especially if you’re into sustainability.

Benefits of Closed-Loop Footwear Production Systems

Challenges Facing Closed-Loop Footwear Production Systems

But hold your horses, closed-loop footwear production systems are not without their challenges. First, the technology needed to dismantle and recycle footwear materials is costly and complex. Brands have to make significant upfront investments, which can be a hurdle for smaller companies. Additionally, there’s a learning curve involved; both manufacturers and consumers need to adapt to new ways of thinking about recycling and reuse. And let’s not forget about logistical challenges. Collecting and transporting used shoes for recycling can be quite an operation, requiring strong infrastructure. But with innovation at its peak, these challenges are merely bumps in the road.

The Future of Closed-Loop Footwear Production Systems

Looking ahead, the future of closed-loop footwear production systems is as bright as a new pair of kicks fresh out of the box. As technology advances, expect these systems to become more efficient and widespread. Imagine a future where every shoe you buy contributes to a cycle of reuse, innovation, and sustainability. In just a few years, the term “waste” could become obsolete in the footwear industry. Brands will continue to join the movement, motivated by consumer demand and environmental responsibility. So the next time you lace up your sneakers, know that you’re potentially contributing to a larger, sustainable change. Here’s to walking further with a smaller footprint!